- Home Page

- Company Profile

-

Our Products

- Strapping Tensioner tools

- Pneumatic Strapping Tools AQD 19

- Manual Tensioner Strapping tools

- Pneumatic Strapping Tools

- Pellet Packaging

- Manual Cord Strap Tensioner

- CORD STRAP LASHING TOOLS

- PET Strapping Tools

- PET STRAP MANUAL TENSIONER TOOLS 19MM

- Strapping Tensioner

- BOX STRAPPING MACHINE

- 19MM Manual Strapping Tool

- BOX STRAPPING MACHINE (BALL BEARING )

- Plastic Strapping Tensioner

- Cord Strap

- Bopp Tape

- Strapping Tensioner tools

- Contact Us

Pneumatic Strapping Tools AQD 19

11500.0 INR/Piece

Product Details:

- Type Tools

- Material Stainless Steel

- Computerized No

- Automatic Grade Manual

- Control System Human Machine Interface

- Selection Mode Manual

- Weight (kg) 1-5 Kilograms (kg)

- Click to view more

X

Pneumatic Strapping Tools AQD 19 Price And Quantity

- 1 Piece

- 11500.0 INR/Piece

Pneumatic Strapping Tools AQD 19 Product Specifications

- No

- Manual

- Human Machine Interface

- Stainless Steel

- Tools

- 1-5 Kilograms (kg)

- Manual

Pneumatic Strapping Tools AQD 19 Trade Information

- MUMBAI NHAVA SHEVA

- Paypal, Cheque, Telegraphic Transfer (T/T)

- 300 Piece Per Month

- 1 Days

- No

- Contact us for information regarding our sample policy

- case, Cartons

- Middle East, Africa, Asia, Eastern Europe

- West Bengal, Rajasthan, Gujarat, Maharashtra, Goa

Product Description

SHREE SALASAR TRADING COMPANY ( IMPORT SALES )

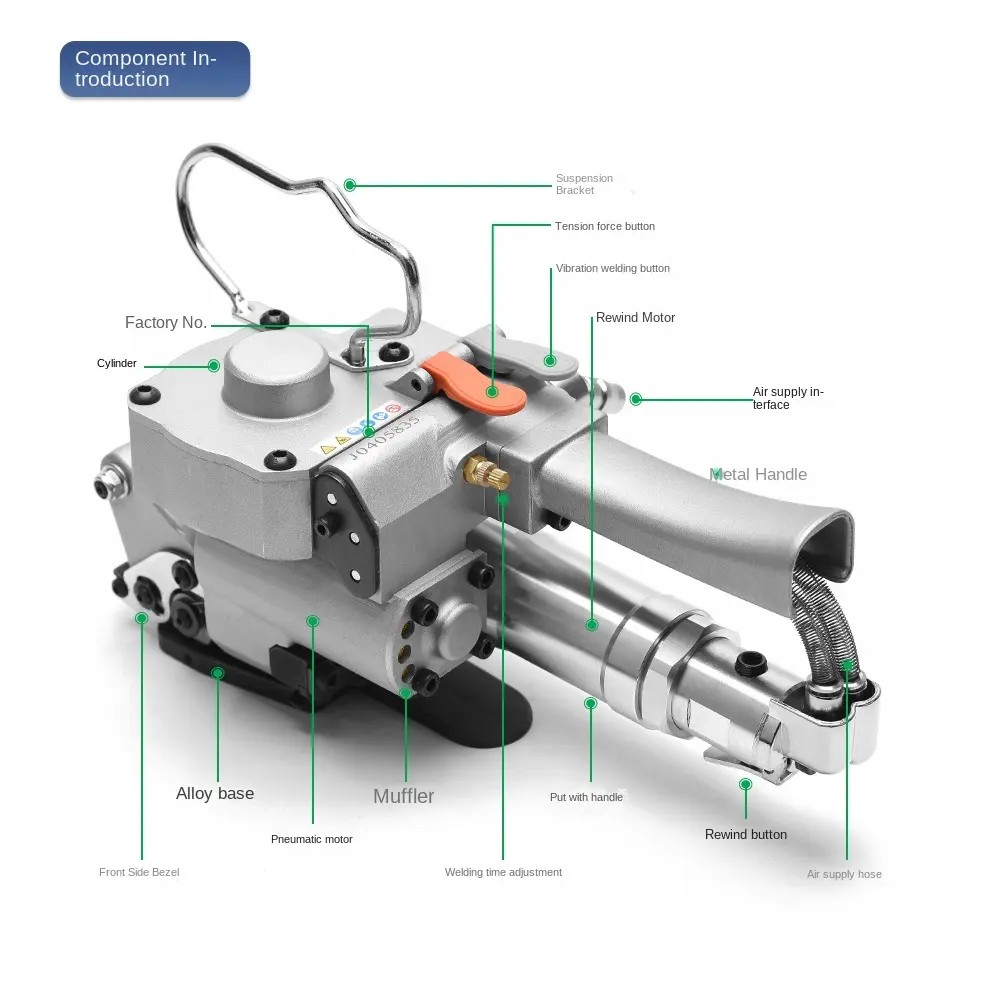

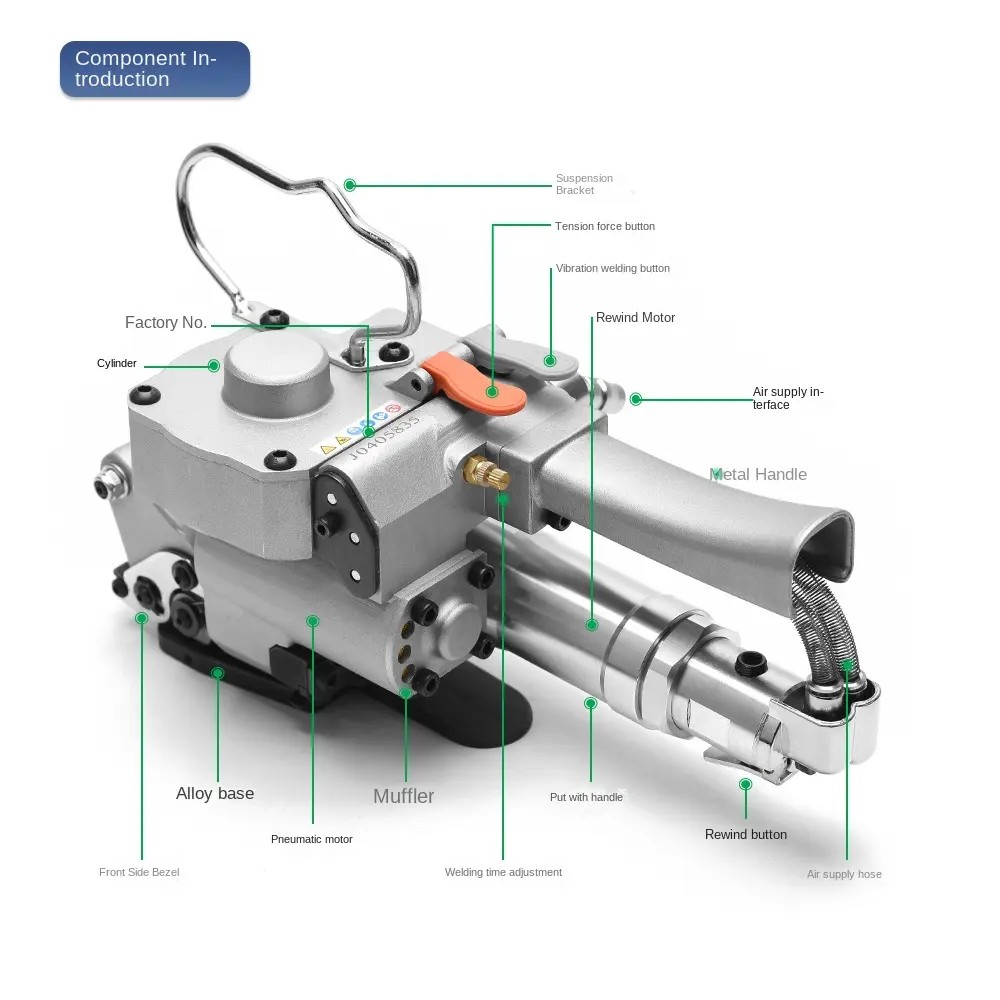

The A19 PET/PP Device Pneumatic Strapping Tool Machine is a handheld, automatic strapping machine designed for securing packages and pallets using either PET (polyester) or PP (polypropylene) plastic straps. Here's an introduction to its key features and benefits:

Key Features:

- Pneumatic Operation: Powered by compressed air, ensuring consistent and reliable strapping. Requires connection to an air compressor (typically around 0.5-0.8 MPa or 72-116 PSI).

- 3500N High Tension Force: Delivers a strong tensioning force of up to 3500 Newtons, making it suitable for securing heavy or bulky items.

- High Welding: Utilizes a friction heat welding method to create a strong and secure seal without the need for separate seals or buckles.

- Automatic Strapping: Offers automated functions for tensioning, welding, and cutting the strap, streamlining the packaging process and improving efficiency.

- Versatile Strap Compatibility: Designed to work with both PET and PP plastic straps, offering flexibility for different packaging needs.

- Adjustable Strap Width and Thickness: Accommodates various strap dimensions, typically ranging from 13-19mm in width and 0.5-1.2mm (or sometimes up to 1.5mm) in thickness, depending on the specific model.

- Handheld and Portable: Its portable design allows for easy movement and use in different locations within a warehouse or production facility.

- Durable Construction: Often made with high-strength alloy materials to ensure durability and a long service life in industrial environments.

- Sealless Operation: Eliminates the cost and hassle of purchasing and handling separate metal or plastic seals.

- User-Friendly Operation: Designed for relatively simple operation, often involving just a few button presses to complete the strapping cycle.

Benefits:

- Increased Efficiency: Automating the strapping process significantly speeds up packaging operations compared to manual strapping.

- Improved Package Security: The high tension force and strong weld ensure that packages are securely fastened, reducing the risk of damage during transit and handling.

- Cost Savings: Eliminating the need for seals reduces material costs.

- Ease of Use: The handheld design and automated functions make it easier for operators to strap packages with less effort.

- Versatility: The ability to use PET and PP straps makes it a flexible solution for various applications.

- Reliability: Pneumatic power provides consistent performance and reduces the risk of tool failure compared to manual tools.

Applications:

This type of strapping machine is commonly used in various industries for securing:

- Pallets of goods

- Bales of materials (e.g., cotton, fibre)

- Wooden crates and cases

- Metal products (e.g., pipes, coils)

- Paper and printing products

- Construction materials

- And other heavy or large items

In summary, the A19 PET/PP Device Pneumatic Strapping Tool Machine with 3500N high welding capability is a robust and efficient solution for businesses looking to streamline their packaging process, enhance the security of their shipments, and potentially reduce material costs associated with strapping.

| Strap Type | Pet strap |

| Model Number/Name | AQD 19MM |

| Pressure | 7 kg |

| Material | electrode Zinc Alloy |

| Brand | SSTC |

| Model Name/Number | AQD 19 |

| Air Pressure | 7 kg required |

| Sealing Type | 2 sc |

| Type | PNEUMATIC Strapping tools |

| Packaging Type | Box |

| Weight | 3.8 Kg |

| Strap Thickness | 0.5-1.5mm |

| Strap Width | 13 mm-19 mm |

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in ' Strapping Tensioner tools' category

"We are mainly dealing in Gujarat."

Call Me Free

Call Me Free